TTA Jump!

Tibial Tuberosity Advancement

Characteristics

MECHANICAL PROPERTIES:

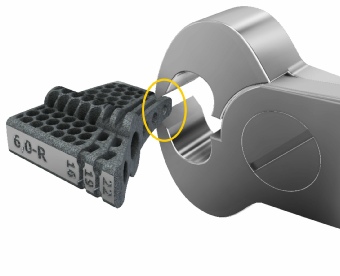

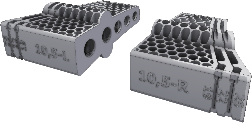

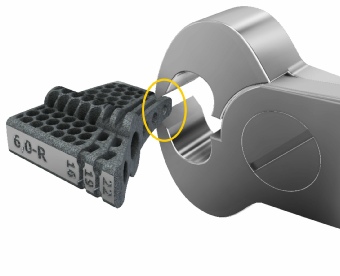

Two hemicylindrical roller distribute the tensile load of the patellar tendon direct from the tuberosity to the tibia via the implant. This is the main reason for the reduced load of the relatively weak bone section near the Maquet Hole.

The implant contains a curved, anatomically aligned design. In comparison to a flat geometry, a curved shape creates additional radial directed forces when tensile forces are loaded. The radial directed forces creates pressure between tuberosity, TTA cage and tibia and stabilize the implant position. The described mechanical advancements ensure the needed stabilization to disclaim screws for a secure and safe positioning. The benefit of the screwless design is self-explaining and reduces the risk of fractures close to the screws.

CUSTOMIZING INTRAOPERATIVELY:

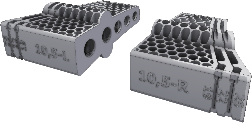

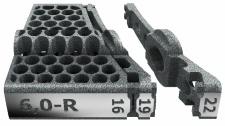

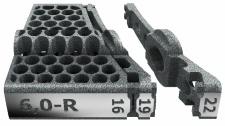

The implant can get customized during the surgery. The necessary implant width can be adjusted intraoperatively by cutting the TTA cage. Three different widths are possible. This property uprises the flexibility and reduces investment and inventory costs.

Shape

Geometry:

Material:

Surface:

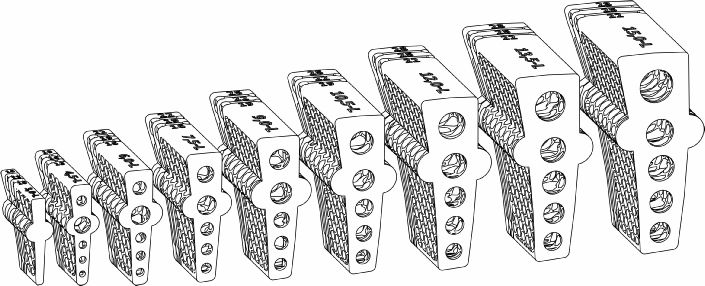

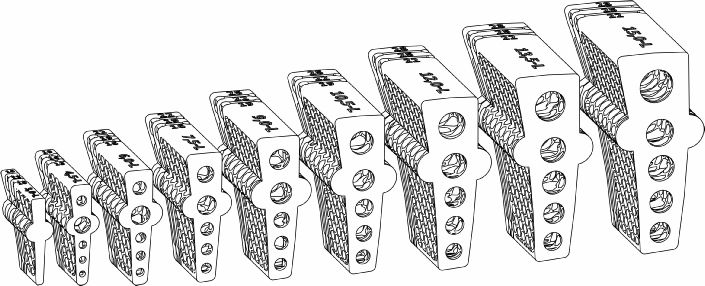

Sizes:

curved and anatomically aligned design,

hemicylindrical roller

Titanium alloy (TiAl6V4, ISO 5832-3,

US-Standard ASTM F1472)

blasted

3,0 to 15,0 - left / right

Biomechanics

Primary Anchorage:

Secondary Anchorage:

form closure

ongrowth and formation of bone stock

Delivery condition: Sterile, ready to use out of the box.

Cuttable TTA Jump! cage for customized implant width

curved osteotomy, anatomically aligned

direct load transfer and bone friendly

customizable implant width